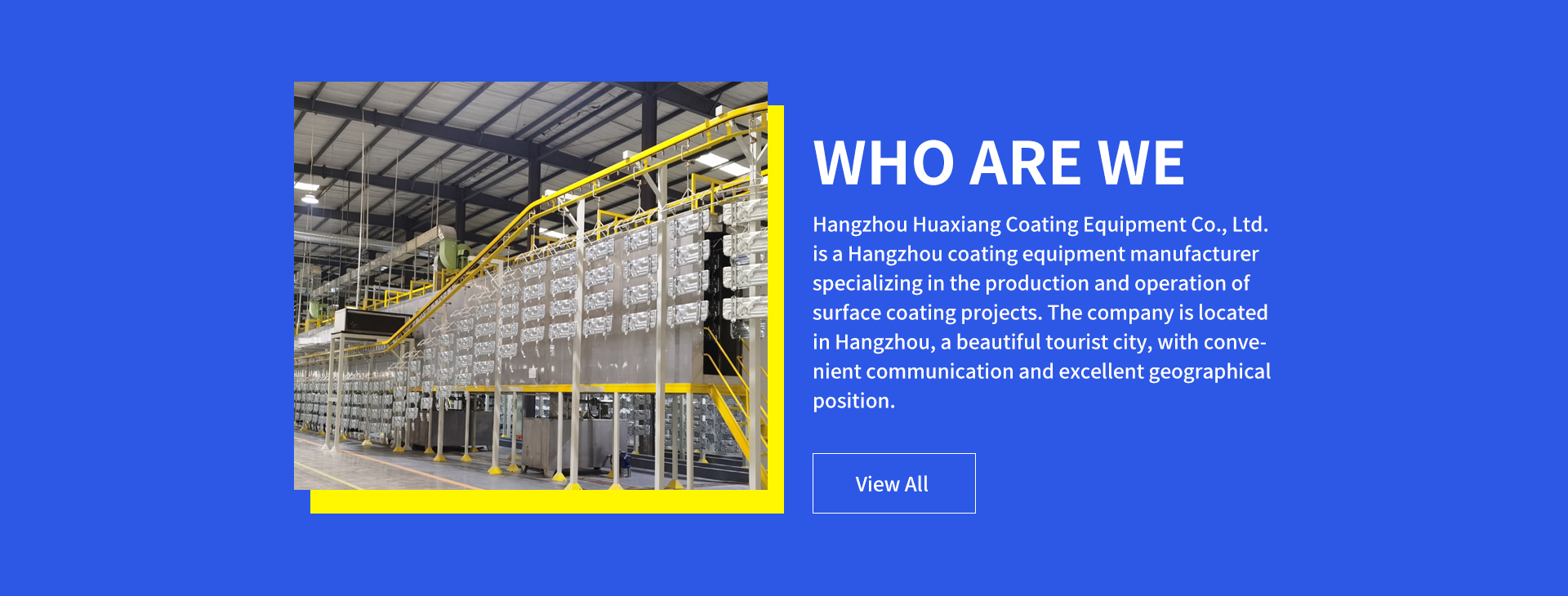

1. Introduction to Industrial Powder Coating Booths

Industrial Powder Coating Booths are specialized enclosures designed for high-volume powder coating applications. These booths feature robust construction, advanced ventilation systems, and efficient powder recovery units. Key components include spray zones, exhaust fans, filtration systems, and lighting, ensuring optimal conditions for consistent, high-quality finishes.

2. Applications of Industrial Powder Coating Booths

These Industrial Powder Coating Booths are widely used in industries like automotive, aerospace, and heavy machinery manufacturing. They are ideal for coating large items such as car bodies, aircraft components, and industrial equipment. Their ability to handle high-volume production makes them essential for large-scale operations.

3. Price Range of Industrial Powder Coating Booths

Prices range from 10,000forstandardmodelsto100,000+ for custom, high-capacity units. Factors influencing cost include size, ventilation efficiency, and additional features like automated powder recovery. While expensive, these booths offer long-term value through durability and productivity.

4. How to Use an Industrial Powder Coating Booth Correctly

Ensure the workpiece is clean and properly grounded.

Adjust ventilation settings to control overspray and maintain air quality.

Use the Industrial Powder Coating Booth’s lighting and spray zones for even coverage.

Regularly clean the filtration and recovery systems to prevent clogs.

Follow manufacturer guidelines for safe and efficient operation.

5. Tips for Choosing an Industrial Powder Coating Booth

Size: Select a booth that accommodates your largest projects.

Ventilation: Opt for advanced airflow systems to minimize overspray.

Recovery System: Choose Industrial Powder Coating Booths with efficient powder recovery to reduce waste.

Customization: Look for customizable features to meet specific production needs.

Budget: Balance cost with features to ensure long-term value.

6. Safety Precautions for Industrial Powder Coating Booths

Wear PPE (respirators, gloves, safety goggles) to avoid inhaling powder.

Ensure proper grounding to prevent electrostatic discharge.

Operate in well-ventilated areas to avoid dust accumulation.

Regularly inspect electrical components and ventilation systems for safety.

7. Design Advantages of Industrial Powder Coating Booths

Industrial powder coating booths are designed for efficiency and durability. Features like high-capacity ventilation, automated powder recovery, and customizable layouts enhance productivity. Their robust construction ensures long-term reliability, even in demanding industrial environments.

8. FAQs on Industrial Powder Coating Booths

Q1: What industries benefit most from industrial powder coating booths?

A1: Automotive, aerospace, and heavy machinery industries rely on them for high-volume production.

Q2: Can industrial booths handle small projects?

A2: Yes, but they are optimized for large-scale operations.

Q3: How to maintain an industrial powder coating booth?

A3: Clean filters weekly, inspect ventilation systems monthly, and follow manufacturer guidelines.

Q4: Are industrial booths eco-friendly?

A4: Yes, their powder recovery systems minimize waste and reduce environmental impact.

Q5: What is the lifespan of an industrial powder coating booth?

A5: With proper maintenance, they can last 10-15 years or more.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com